The Benefits of Polyurethane Parts

Polyurethane is Extremely Versatile

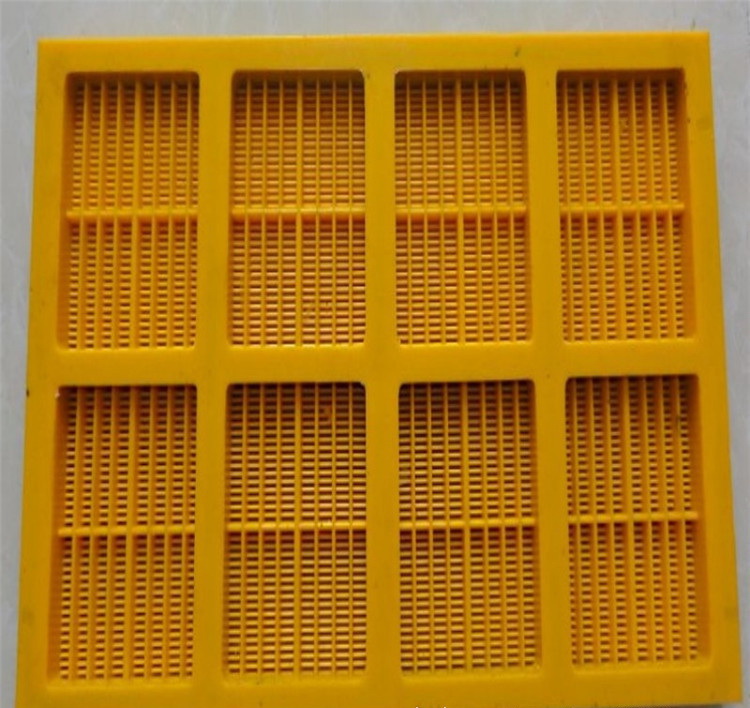

What makes urethane incredibly useful is its versatility. Urethane starts as a viscous liquid prepolymer resin that in mixture with a curing agent. Then, pouring it or injecting it into a mold ensues. Because urethane exists in a liquid state before it cures into a solid urethane elastomer, it can take on the shape of practically any mold cavity. There are essentially endless products that we can manufacture from urethane. The only limit is the engineer designing the product.

Polyurethane Parts Significantly Reduce Noise and Absorb Vibrations

Urethane parts are excellent for applications where noise abatement and vibration dampening are key. Industries across the world consistently use urethane to control decibel levels in the working environment as well as dampen impact related vibrations. Because of urethane’s ability to absorb vibrations and hold up against repeated extreme collision, it has become the #1 material in parts used for high impact applications where energy absorption and noise abatement are necessary.

Urethane Has Many Different Grades, Formulations, and Hardness Ranges

Urethane has many different grades and hardness ranges (durometer) whose tailoring to specific applications is possible. There are a host of different compounds such as polyesters, PPG and PTMEG polyether’s, TODI and MDI based systems, etc., that can be used to manufacture urethane parts. The parts produced from each of these compounds have their own unique set of uses, price, and physical properties. This allows the product to be designed and priced to each specific application. This can help increase component lifespan and cut costs.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com