The Advantages of Polyurethane Screen

Categories: Industry news

Application: The Advantages of Polyurethane Screen

InquiryMain description:

The Advantages of Polyurethane Screen

The Advantages of Polyurethane Screen

The Advantages of Polyurethane Screen

Traditional screens are usually made of stamping, weaving or tailor welding, and are made of carbon steel, stainless steel or alloy steel. This kind of screen will be severely impacted by ore, resulting in serious wear and tear. Moreover, due to the high frequency of the vibrating screen, the welds are prone to fatigue and cracking, the service life is short, and the replacement is frequent, which seriously affects the production efficiency of the vibrating screen. However, the screen surface of today's high-frequency screens is generally assembled from multiple screens.

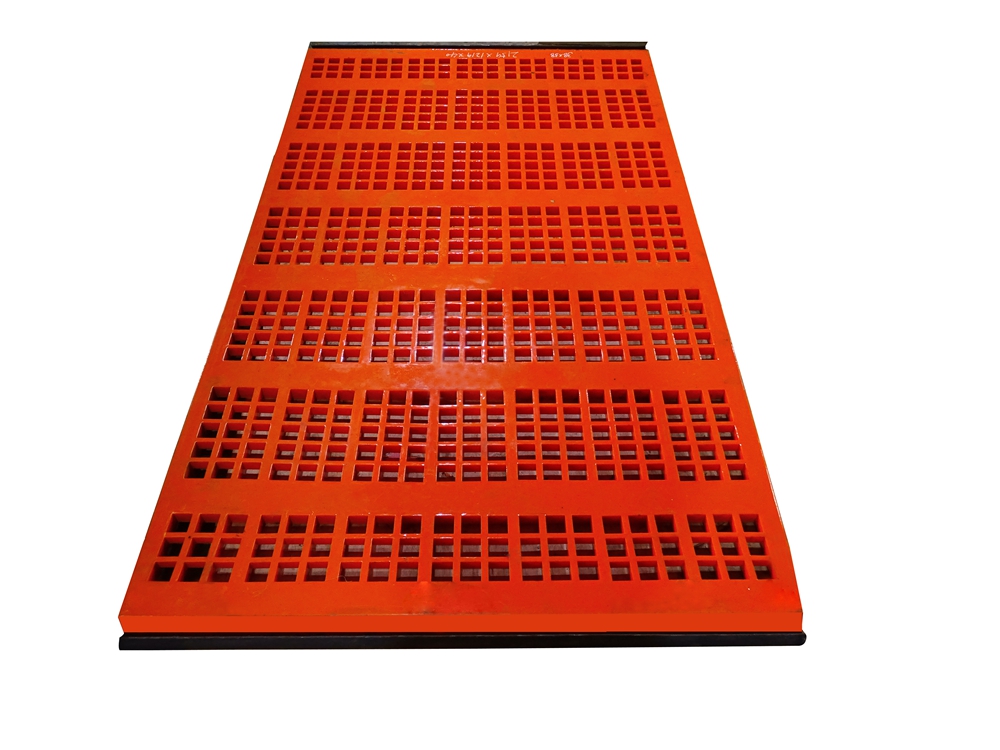

Application of polyurethane screen

At present, polyurethane screens have been widely used in vibrating screens in mining, coal and other industries. Because people find that polyurethane (Polyurethane) elastomer products have multiple advantages, such as wear resistance, oil resistance, aging resistance, tear resistance, impact resistance, high elasticity, strong vibration absorption and so on. Therefore, the polyurethane screen made of this material also has the characteristics of light weight, high screening efficiency, not easy to block holes, wear resistance, impact resistance, and long service life.

The comparative advantages of polyurethane screens and ordinary metal screens are as follows:

①Long service life

Because the polyurethane screen uses steel wire rope as the skeleton material, and polyurethane itself has high impact absorption and high wear resistance, it has high tensile strength. Under this condition, its service life is 3-5 times longer than ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber.

② High screening efficiency

The screen surface has self-cleaning performance, no hole blocking, and high screening efficiency. Due to the strong water permeability and large cone angle of polyurethane, it can well prevent the adhesion of wet fine particles, so it is suitable for screening and grading of wet fine materials.

③High screening accuracy

Polyurethane screen (Polyurethane) production process adopts die-casting process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can well meet the user's requirements.

④Easy to install

Polyurethane screens are much lighter than ordinary metal screens and are easy to carry, reducing the workload of on-site installation or replacement and maintenance.

⑤ widely used

Polyurethane screens are used in metal separation and mining industries such as hydropower stations and building materials, and can handle the classification of 0-5mm materials. The product is water-resistant, corrosion-resistant, aging-resistant, easy to replace and maintain. Polyurethane has low density and lighter weight than metal screen surface, which can reduce production unit consumption, so it can meet the requirements of large-scale development of screening machines.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags