The Process of Producting Polyurethane Screen

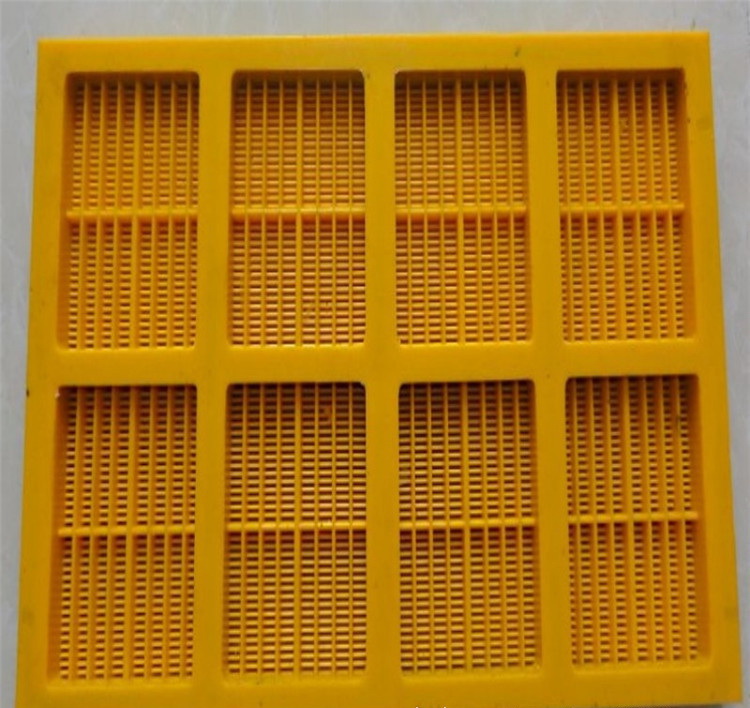

Polyurethane screen is a material commonly used in screening and filtration, and its manufacturing process is mainly realized by injection molding process. The following is a brief introduction to the injection molding process of polyurethane mesh.

1. Raw material preparation: The main raw materials of polyurethane screen are polyurethane resin, curing agent, auxiliary agent and so on. These raw materials need to be prepared before manufacturing and ensure their quality meets the requirements.

2. Melting: Mix polyurethane resin and curing agent according to a certain ratio and heat to molten state. At this time, additives such as plasticizers and pigments can be added according to different needs.

3. Injection molding: Inject molten polyurethane material into the mold for molding. The mold is usually made of steel and its internal design depends on the desired screen shape and size.

4. Cooling: After the injection molding is completed, the polyurethane material in the mold needs to be cooled to room temperature. This process takes a certain amount of time, usually between a few minutes and a few hours.

5. Demolding: When the polyurethane material is sufficiently cooled, it can be released from the mold. At this time, subsequent processing and treatment can be carried out, such as deburring, grinding and so on.

6. Inspection: Finally, the quality inspection of the manufactured polyurethane screen needs to be carried out to ensure that it meets the requirements. The inspection content mainly includes appearance, size, strength and other indicators.

In short, the injection molding process of polyurethane screen mesh is relatively simple, but the quality and process parameters of each link need to be strictly controlled to ensure that the manufactured products have good performance and reliable quality.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags