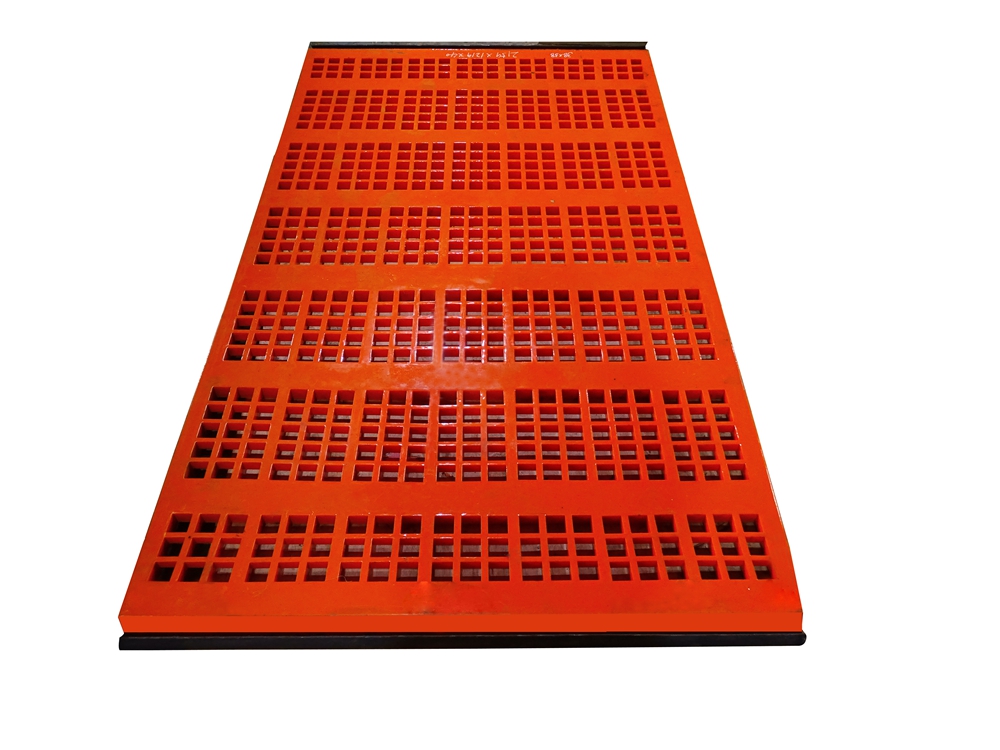

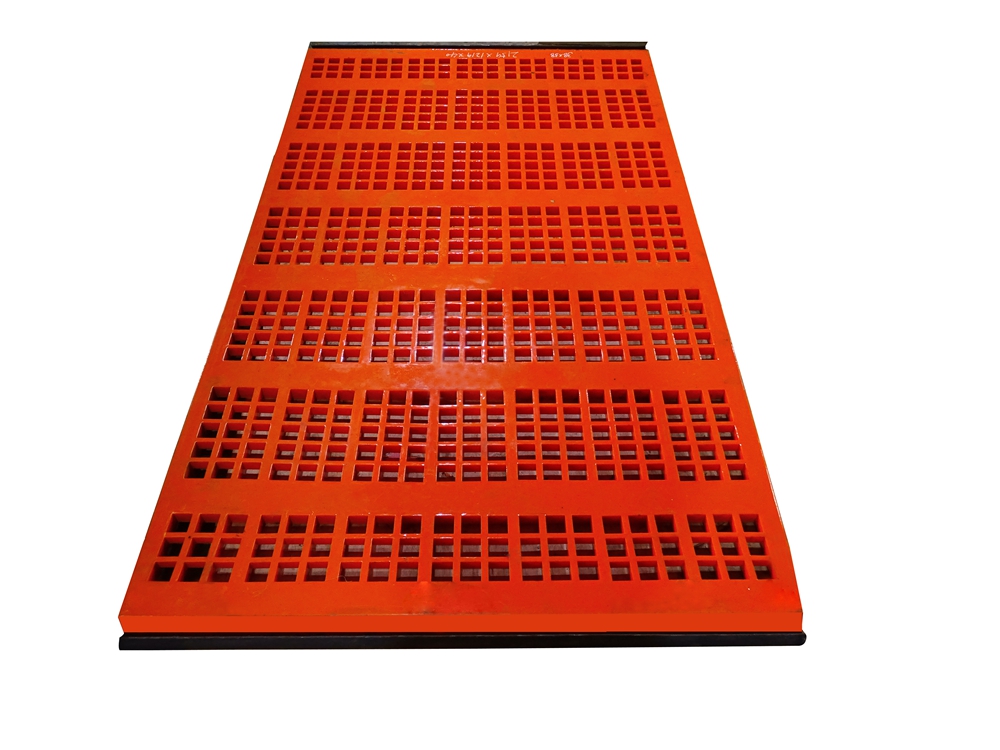

What factors affect the service life of polyurethane screen

1. The impact of unreasonable use on the life of polyurethane screen

After choosing the correct polyurethane screen, it is necessary to use it reasonably to ensure that the performance and life of the polyurethane screen are maximized. However, many users tend to ignore this point in the process of using polyurethane screens.

For example, the tensioned screen is easy to be loosened by large pieces of material during use, and the tension bolts need to be tightened regularly. If the time is long, the tension bolts are loose and not tightened, resulting in knocking between the screen and the support ribs, affecting The life of the screen. At the same time, there is also a material inlet design. It is recommended that the feeding method should not be vertical to the screen surface, and the feeding direction should be inclined along the logistics direction, and the feeding height should not exceed 400mm to prevent excessive impact force from damaging the screen.

2. Unreasonable processing technology also affects the life of polyurethane screen

In the case of the same raw material of polyurethane screen, its processing technology is the main factor affecting its quality. The polyurethane screen should be treated with mold and skeleton before pouring. No matter the temperature or the oil stain on the surface of the skeleton, it should be treated accordingly. , if the surface oil stains are not treated properly, it will affect the bonding between the skeleton and polyurethane, and it will easily fall off, and the temperature control is unreasonable, which will cause bubbles or burnout during pouring, which will affect the life of the polyurethane screen.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags