Polyurethane Elastomer

The comprehensive performance of polyurethane elastomer is superior, and any other rubber and plastic are incomparable. And polyurethane elastomers can be processed according to the requirements of processing molding, almost any kind of conventional processing of polymer materials, such as mixing molding, liquid pouring, melting injection, extrusion, calendering, blow molding, liquid coating, spinning and mechanical processing. Polyurethane elastomer has a wide range of applications, and its products are almost widely used.

Polyurethane elastomers have excellent comprehensive performance, mainly in the elastomers have many valuable properties from rubber to plastic.

1. Wear resistance: the wear resistance of polyurethane elastomer is generally about 3-5 times that of natural rubber, enjoying the reputation of "wear-resistant rubber"; The wear resistance of polyurethane elastomers is very prominent, and the test results are generally within the range of 0.03 ~ 0.20mm3/m, about 3 ~ 5 times that of natural rubber. In practice, due to the influence of lubricant and other factors, its effect is often better. The wear resistance is closely related to the tearing strength and surface condition of the material. The tearing strength of polyurethane elastomer is much higher than that of other rubber, but its friction coefficient is not low, generally above 0.5, which requires attention in actual use to add oil lubricants, or add a small amount of molybdenum disulfide or graphite, silicone oil, tetrafluoroethylene powder, etc., in order to reduce the friction coefficient and reduce friction heat generation. In addition, friction coefficient is also related to material hardness and surface temperature and other factors. In all cases, the coefficient of friction increases with decreasing hardness and increases with increasing surface temperature. The maximum value is about 60℃.

PU Board

2. Wide hardness range: the hardness range of polyurethane elastomer can be low in Shao A10, high hardness can reach Shao D95, the hardness of rubber extends to the hardness range of plastic, more valuable is that polyurethane elastomer in the case of high hardness according to a good rubber elasticity and elongation; High hardness can be obtained at the cost of greatly reducing elasticity and elongation. It is reported that when the hardness is higher than 75D, the elasticity will be severely lost, and when the hardness is higher than 85D, the material becomes inelastic.

PU Sheet

3. High strength: the tensile strength and tearing strength of polyurethane elastomer is much higher than that of universal rubber under the hardness of rubber; Their impact strength and bending modulus are much higher than those of plastics.

PU board

4 oil resistance: polyester polyurethane elastomer oil resistance is not less than butadiene rubber, and polysulfide rubber equivalent;

PU tube

5. High bearing capacity: because polyurethane elastomer can improve the hardness under the premise of maintaining rubber elasticity, so as to achieve a high bearing capacity, which is not comparable to other rubber;

PU board

6. Good vibration absorption performance: the effect of polyurethane elastomer on the alternating camp shows obvious hysteresis phenomenon. In this process, part of the energy of external force is consumed in the interior of polyurethane elastomer and converted into heat energy. Therefore, polyurethane elastomer has obvious vibration absorption performance, also known as damping performance, and its radiation resistance and breathable resistance

PU rod

7. Low temperature resistance: polyurethane elastomer has good low temperature performance, brittle containment is generally very low (-50℃-70℃), some formula varieties catalytic temperature is lower than -70℃, so polyurethane elastomer products are especially suitable for cold environment;

PU coating

8. Radiation resistance and ozone resistance: in polymer materials, polyurethane has outstanding radiation resistance and ozone resistance;

PU wheels

9. Mold resistance: polyether polyurethane has good mold resistance, which used to be grade 0-1, and basically does not grow mold.

PU scraper

10. Electrical property: The electrical insulation property of polyurethane elastomer is better at general working temperature, roughly equivalent to the level of neoprene rubber and phenolic resin. Because it can be cast and thermoplastic molding, it is often used as electrical component sealing and cable sheathing materials. Due to its large molecular polarity and affinity for water, polyurethane elastomer's electrical properties change greatly with the ambient temperature, and it is not suitable for the use of high-frequency electrical materials. In addition, the electrical properties of polyurethane elastomers decrease with increasing temperature and increase with increasing hardness of materials.

PU rollers

11. Processing method, wide applicability. Polyurethane elastomers can be molded by plasticizing, mixing and vulcanizing processes (MPU) like general rubber; It can also be made into liquid rubber, casting molding or spraying, potting, centrifugal molding (CPU); It can also be made into granular material, which is shaped by injection, extrusion, calendering, blow molding and other processes (referring to CPU) like ordinary plastics. Molded or injection molding parts, in a certain range of hardness, can also be cut, grinding, drilling and other mechanical processing. Due to the diversity of processing, polyurethane elastomers are widely applicable and widely applied.

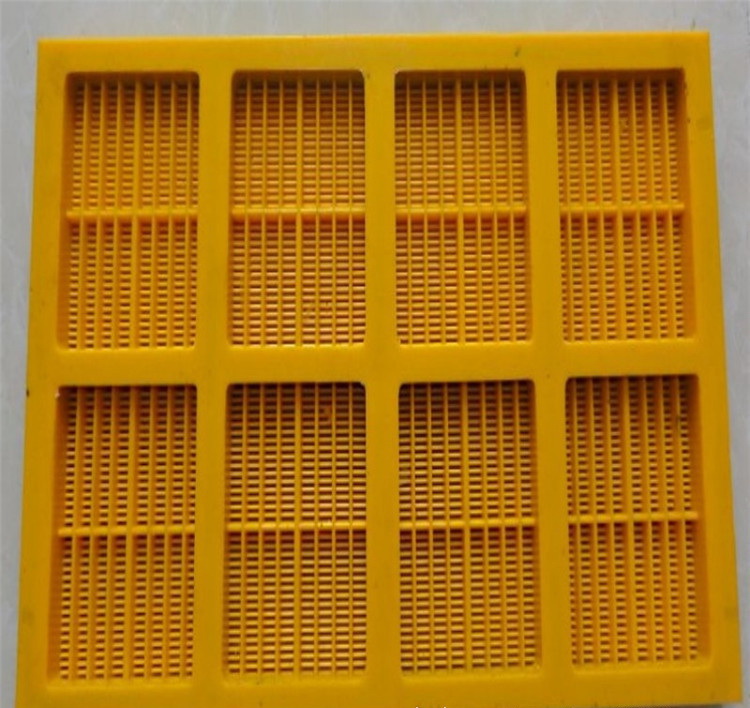

PU screen

12. Industrial performance: polyurethane material has excellent biocompatibility. Acute and chronic toxicological tests and animal tests have confirmed that medical polyurethane material is non-toxic, no distortion, no allergic reaction and other adverse side effects. The adjustable range of performance is large. A number of physical and mechanical performance indexes can be changed within a certain range through the selection of raw materials and the adjustment of the formula, so as to meet the different requirements of users on product performance.

PU belt

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags