Introduction to the Professional Application of Polyurethane Screen

1. Long service life. Due to the high strength absorption impact force, high wear resistance, so its service life and metal screen compared with 8-10 times.

2. Polyurethane screen production material is a polymer organic elastomer, has the best wear resistance, flexure resistance, large bearing capacity. The raw material of polyurethane screen has been specially treated to ensure that it never takes off the layer under the action of long-term alternating load.

3. High screening efficiency. Because the polyurethane screen adopts imported raw materials, it has good elasticity and tensioning performance. At the same time, because of the second harmonic high frequency vibration of the screen, it can effectively avoid plugging phenomenon in the dynamic situation. |

4. wide range of application, professional applicability is stronger. Polyurethane screen is professionally used in metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), nonferrous, yellow, coal, chemical, building materials and hydropower engineering, building materials and other metal mining, abrasive waste treatment, quarry and other industry materials washing, screening, classification and other industries. 0.1mm-170mm range of all kinds of material screening, whether dry screening, wet screening will not affect the screening efficiency.

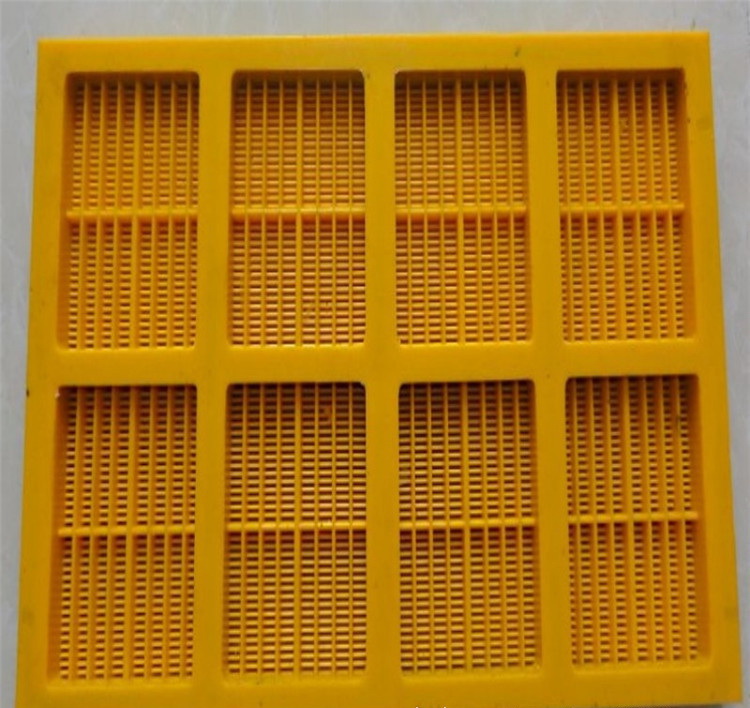

5. High screening accuracy. The production process of polyurethane screen determines the rule of the product pass, accurate aperture and high screening quality

6. Low noise at work. According to the actual measurement, the same screen machine using polyurethane screen than metal screen can reduce the noise 5-20 decibels, and greatly reduce the dust flying, so that the production site has a quiet clean working environment.

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags