Polyurethane has a wide range of applications

1. Polysilicon:

Polysilicon and other semiconductor materials have high purity requirements in the production process, so the materials should be prevented from being contaminated in the production process. One important source of pollution is metal tools. Therefore, in the production, materials must avoid contact with metal tools, polyurethane products and polyurethane lined tools is a very ideal choice for many customers in the polysilicon industry Chengdu Longyuan to provide polyurethane products, including raw material containers, transportation tools, polyurethane parts production line, crushing table, packaging tools. Products wear-resistant, long service life, no pollution to the product, widely welcomed.

2. Logistics and Transportation:

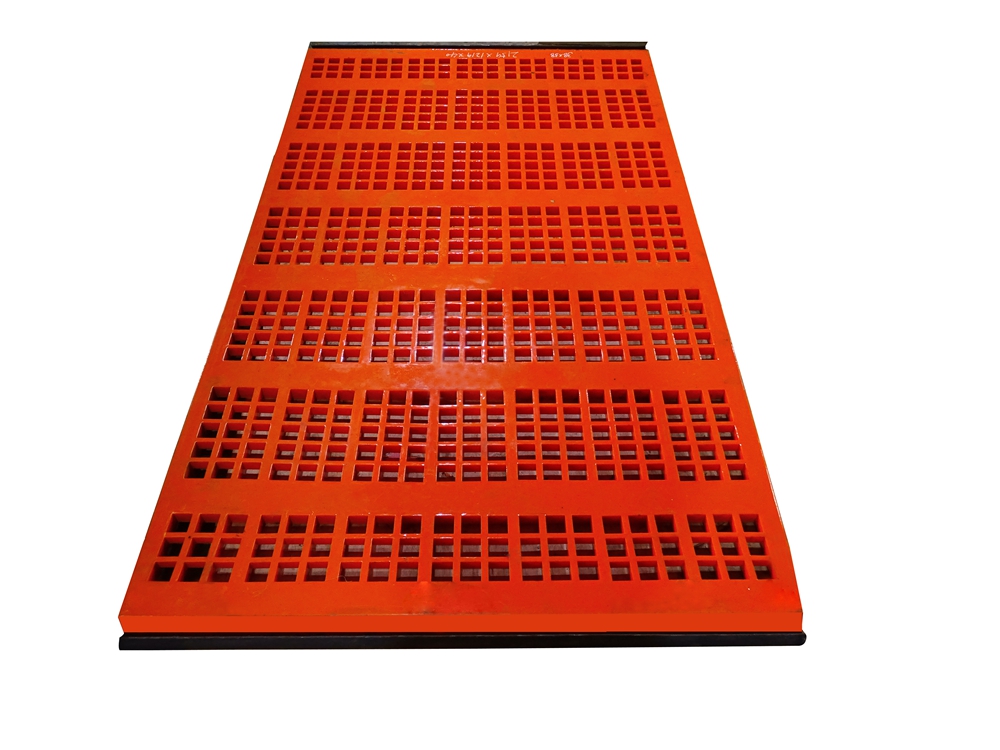

Elastic polyurethane products, including polyurethane wheel, polyurethane rubber roller, polyurethane cushion, polyurethane coated forklift wheel, effectively improve the service life of equipment, protect product safety, provide security for logistics warehousing enterprises, reduce costs, polyurethane materials because of its high wear resistance, good elasticity, oil resistance, chemical resistance and other characteristics, It is widely used in the logistics and transportation industry. Transmission parts such as rollers, conveyor belts, transmission cots, cushion pads, wear pads, anti-collision blocks and many other parts are made of polyurethane materials. A large part of forklift wheels, logistics shelves and so on are also polyurethane materials. Polyurethane products have good performance, long service life, can be applied to different environments, and easy to shape, can be customized at low cost according to different conditions of various polyurethane non-standard parts, shaped parts, etc.

3. Automobile Industry:

The application of polyurethane in automobile is everywhere. The interior decoration, parts, fixture on the production line, auxiliary materials, test tools and so on can not be separated from polyurethane. Polyurethane elastomer has wear resistance, good resilience, high pressure resistance, oil resistance and other characteristics, widely used in automobile manufacturing, often used as transmission roller, logistics shelf fixed parts and anti-collision parts, stamping pad, anti-collision strip, limit device and fixture etc.. The excellent characteristics of polyurethane ensure the safety of products and equipment in the production process, prolong the service life of equipment, and improve the overall benefit.

4. Isostatic pressure:

Ceramic, graphite, hard alloy, permanent magnet materials and other powder materials isostatic molding to provide high quality isostatic pressure mold rubber sleeve. Rich industry experience, advanced professional materials for isostatic pressure industry, win to provide customers with professional isostatic pressure solutions. At present, there are two kinds of isostatic pressure mold (rubber sleeve) widely used, polyurethane isostatic pressure mold and rubber isostatic pressure mold. In comparison, polyurethane mold has obvious advantages: long service life. Polyurethane has the characteristics of oxidation resistance, oil resistance and chemical resistance, good rebound after long time use, no deformation and ensure accuracy. After the rubber isostatic pressure die is used for a long time, the surface will be oxidized, resulting in paste. The application range is wide and the molding accuracy is high. The hardness of polyurethane material can be adjusted in a wide range. According to different use environment and process, it can be made into a very soft rubber sleeve, which is convenient for pressing special-shaped parts, and can also be made into a mold with high hardness, to ensure the rigidity of loading, and to ensure the strict requirements on the size of the finished product. Smooth surface, less finishing. Improve efficiency and save cost.

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags