What are the advantages and use advantages of polyurethane screen

1. Polyurethane screens made of different materials have a great influence on the screening efficiency of various materials. Vibration or beating frequency of various materials on the screen and screen can increase the screening of materials. quantity. And the bonding between separable materials increases more loose particles that can pass through the mesh.

2. Screen size: The larger the screen hole, the higher the productivity per unit screen area and the higher the shielding efficiency. However, the size of the mesh depends on the purpose and requirements. If you want the mesh material to contain less than mesh openings. If the fine material is as small as possible, a smaller sieve opening should be used; on the contrary, if it is required to contain as many particles larger than the specified particle size as possible, the sieve opening should not be too large. The specified granularity is used as a limit for the grid width.

3. Vibration force of polyurethane screen: Polyurethane screen is the vibration source of vibrating screening machine. The size of the exciting force is determined according to the size and material handling capacity of the vibrating screen. The weight of the screening machine is different from the processing volume, and the size of the vibration motor used is different. If the exciting force is too large, the vibrating screen will be broken due to the excessive exciting force. If the excitation force of the vibration motor is too small, the treatment effect cannot be achieved, and the accumulation of materials may be caused due to the excitation force being too small.

Advantages of polyurethane screen:

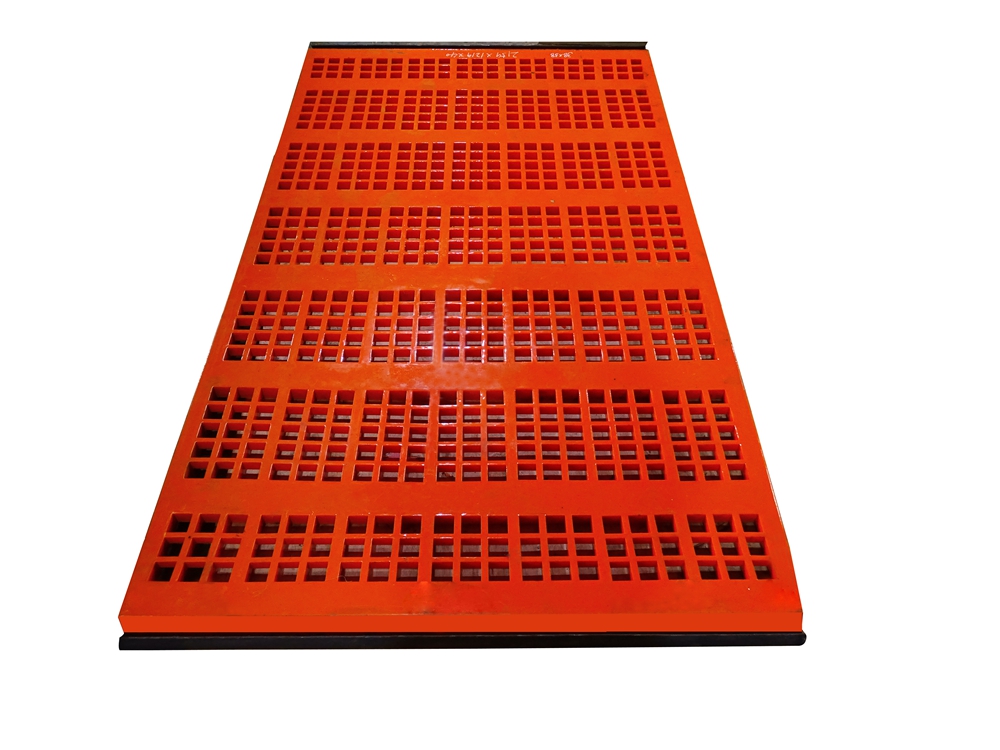

(1) According to the shape of the material, the rubber screen and screen can be designed to have different hole shapes.

(2) The rubber screen and screen are light in weight, which is convenient for on-site loading and unloading.

(3) The rubber screen and screen have greater resistance, which can reduce noise.

(4) The elasticity of the rubber screen and the screen can increase the beating frequency of the material and improve the screening efficiency.

(5) Various skeleton materials can be added to the rubber screen and screen during the forming process to prolong the service life.

Advantages of polyurethane screen

1. Long service life and large carrying capacity. Since the polyurethane elastic screen uses steel wire rope as the skeleton material, and polyurethane itself has a very high elastic modulus, high strength to absorb impact force and high wear resistance, it has high tensile strength, and its bearing capacity is that of rubber screen. 2.5 times or more. Its service life is 8-10 times higher than that of ordinary metal screens, 3 times that of stainless steel sieve surfaces, and 3.9 times that of natural rubber. It is currently the best wear-resistant sieve surface material in the world. The production material of polyurethane screen is a polymer organic elastomer, which has excellent wear resistance, flex resistance and large bearing capacity. The raw materials for the production of polyurethane screens have been specially treated to ensure that they will never delaminate under long-term alternating loads.

2. High screening efficiency. The screen surface has self-cleaning performance, no hole blocking, and high screening efficiency. Due to the strong water permeability of polyurethane and the large sieve cone angle (140°), it can effectively prevent the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine particles. The polyurethane screen of our factory adopts imported raw materials, and its elastic body and its own good relaxation performance can effectively avoid hole plugging under dynamic conditions.

3. It has a wide range of applications and stronger professional applicability. It is suitable for any type of vibrating screen machine and can be made by measuring machine. Polyurethane screens are professionally used in hydropower stations, building materials and other metal beneficiation industries. Screening of various materials within the range of 0.1mm-170mm, regardless of dry sieving or wet sieving, will not affect the screening efficiency. The superiority of the polyurethane screen surface is more fully demonstrated for the dehydration and mediation sieve within the range of 0.5m-3mm. The product is water-resistant, corrosion-resistant, aging-resistant, easy to replace and maintain. Polyurethane has a low density (1.32kg/m 3 ), is lighter than metal screen surfaces, and can reduce production unit consumption, so it can meet the requirements of large-scale development of screen machines.

4. High screening precision. The production process of the polyurethane screen adopts the mold casting process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can well meet the requirements of the user. It is easy to install, easy to replace and repair. This product is suitable for any type of screening machine. It is light in weight and is suitable for on-site installation or replacement and repair, which greatly reduces the workload.

5. The working noise is low, meeting the national environmental noise standards. According to actual measurement, the same sieve machine using polyurethane screen can reduce noise by 5-20 decibels compared with metal screen, and greatly reduce dust flying, so that the production site has a quiet and clean working environment.

6. Significant economic benefits. Although the price of polyurethane rubber screen surface is higher than that of metal screen plate, if the factors such as screening efficiency, maintenance cost and service life are considered comprehensively, it will be found that the overall benefit of polyurethane screen surface is much better than that of ordinary metal screen surface. According to the survey, every ton of polyurethane rubber screen can save 45 tons of steel. Save more than 40,000 yuan in maintenance costs. Therefore, replacing steel screen surfaces with polyurethane screen surfaces will be an inevitable choice for most enterprises in the future.

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags