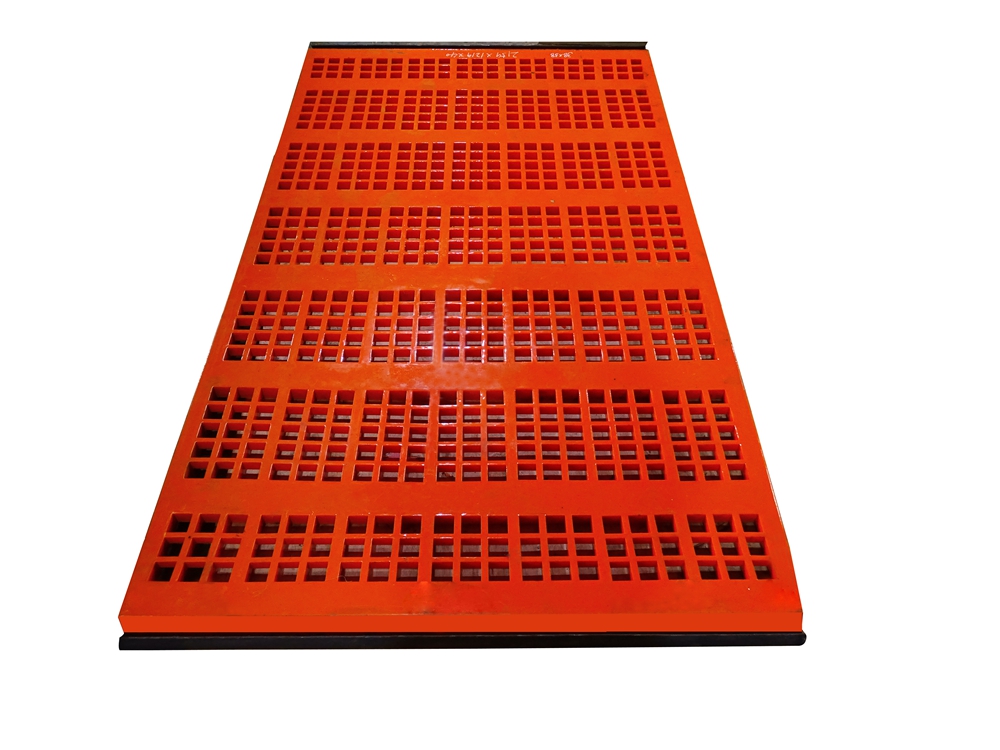

About the Mining Polyurethane Screen

Polyurethane screens are mainly used in mines and quarries. Take the application of polyurethane screen in the coke screening project as an example. The main aggregate used in coke production and screening is bituminous coal. Polyurethane screen is deeply concerned by coke screening enterprises for its high screening rate, high productivity, and long service life.

The quality of the screened material depends largely on the performance of the polyurethane screen, processing technology, and vibrating screening machinery. In order to produce high-quality coke that meets the needs of the project, we need a reasonable selection of coal, plus a good screening of polyurethane screens to produce coke with particle specifications that meet the requirements. Therefore, it is necessary to choose a polyurethane screen with excellent quality to ensure that the project is not affected.

Advantages of polyurethane screens in the mining industry

1. Polyurethane screen can adjust the coarse crushing particle size and the appearance of iron inclusion, which can prolong the service life of the crusher.

2. Add the inclination of the buffer bins and material transport channels.

3. Lined with polyurethane screen to prolong the service life of the equipment.

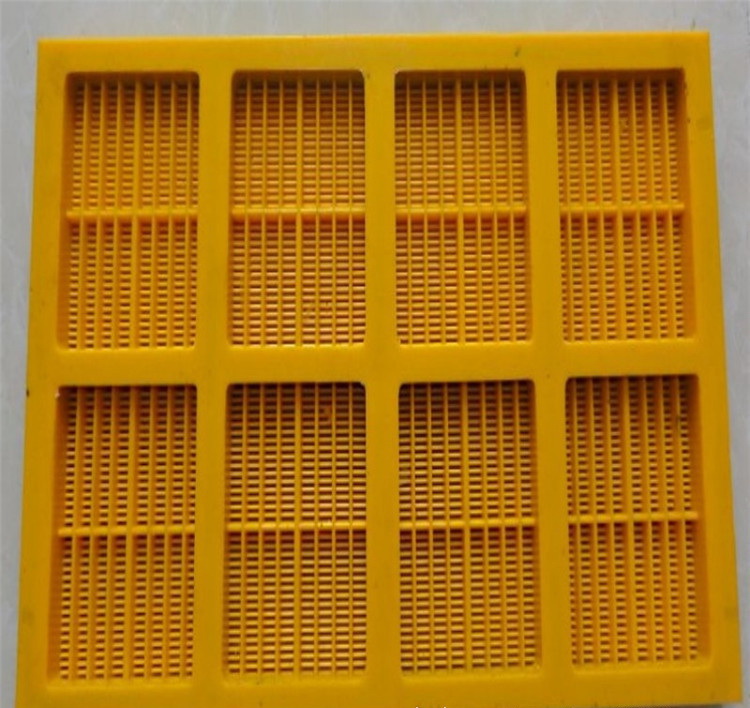

Features of polyurethane screens in mining applications

1. Long service life and large carrying capacity.

2. High screening efficiency.

3. High screening accuracy.

4. Low noise.

5. Significant economic benefits.